Jetson (USA)

Development and production of a flying car

Are you ready for a personal flying vehicle?

Have you ever thought about a car that could easily turn into a small plane and take you to your destination without wasting time in traffic jams?

This dream is becoming a reality faster than you think, thanks to Jetson One and, in small part, 3D printing.

Jetson One is a passenger aircraft. The company is trying to make flight more accessible to the masses by blurring the distinction between the ability to drive a car and the ability to fly a plane.

“When you look at the car, you immediately know: oh yes, I can drive that. We want people to feel the same way when they look at a plane,” says Alec Bialek, head of research and development at Jetson.

I believe I can fly

Jetson’s goal is to make flying, and especially personal flying, accessible to all. The story of Jetson’s founding is very similar to the history of many successful companies that begin with the words: “there were two guys…” They were Tomasz Patan and Peter Ternström, both of whom were interested in Star Wars, helicopters and airplanes.

They had the crazy idea to make a flying vehicle so extremely light that it wouldn’t have to go through all the certification procedures normally required for full-sized aircraft. With this in mind, there was a huge push to make Jetson One as light as possible. Any weight saved in the aircraft counts. It also affects flight time. When you don’t have wings, lightweight propellers are all that keep you in the air.

3D printing lets you fly sooner

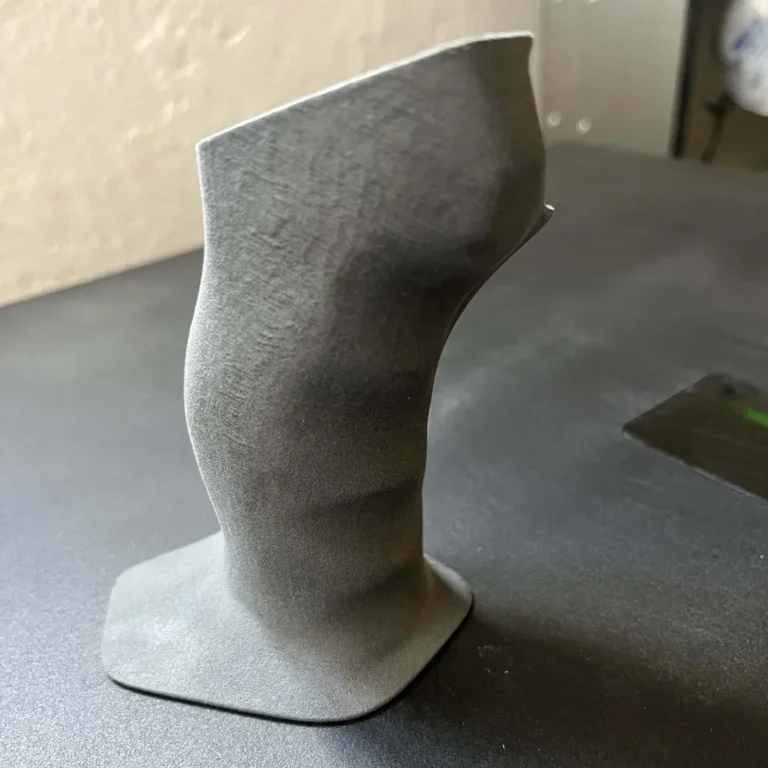

Since the Jetson One is extremely weight sensitive, it had to be manufactured using lightweight methods. And that’s where 3D printing is hard to replace. Additive manufacturing has given Jetson a big advantage when it comes to making hollow structures and very narrow grid patterns that make the parts stiff and strong enough, but also keep as much of the weight out as possible.

Before 3D printing became popular, aircraft manufacturers had to make a lot of moulds to prototype every part of the aircraft. It was a long and expensive process. Engineers at Jetson were able to skip that process, at least until they were happy with the design produced by 3D printing technology.

“We use the printers to make prototypes because we’re trying different things. It’s also nice to model something in CAD software, print it out and physically hold it in your hand and put it on a vehicle. It’s a way you can see if you like it,” Alec Bialek notes. “When 3D printing is so cheap, so accessible, and so fast, it’s actually a really great tool for checking your own designs”, concludes Bialek.

Prototyping is not the only use of additive manufacturing at Jetson. Some final parts are also printed on a 3D printer. If there are unique components that only appear once on a vehicle, it would be very expensive to produce them by casting or molding. Even if there are multiple components on one vehicle and they should eventually be mass produced, it is also better for the company to start with 3D printed parts, and if the demand for the Jetson One is high enough, then it can go into mass production.

“The higher quality associated with SLS is pleasing to us”

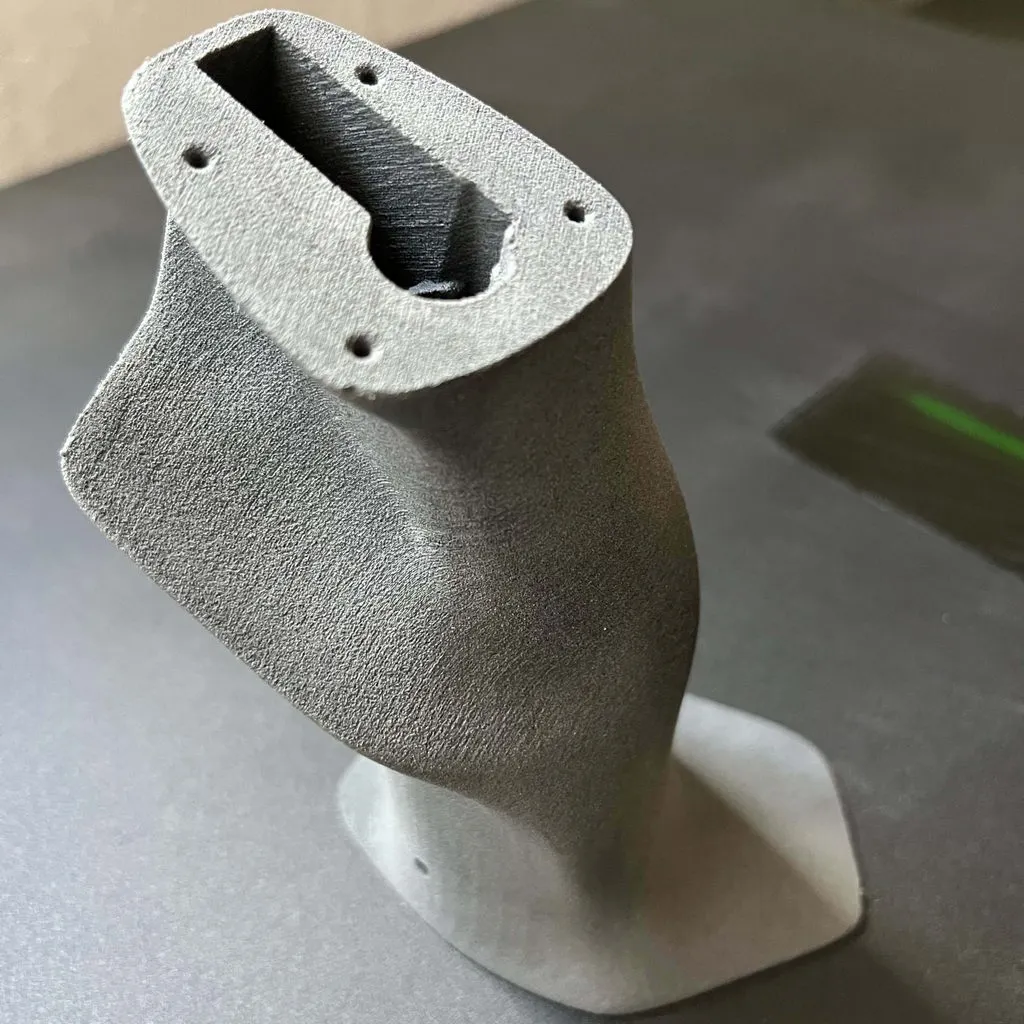

Jetson chose to use SLS 3D printing because of the high quality of the printed parts, extremely good accuracy and strength, and the absence of support structures well known from other popular technologies such as FDM or SLA.

“The print quality is much better than FDM. Since Jetson One is a premium vehicle, we care about the quality of the parts we put out and the quality associated with SLS is unmatched. The material properties are better compared to FDM and there is no need for support material. This is a big advantage when we are trying to lighten our structures heavily”, says Alec Bialek.

Lisa X - not just a prototyping tool

Jetson engineers use the X press to print the brackets that hold the motor speed controllers and inverters. The bezel trim for the instrument panel, as well as the GPS antenna, are also made by additive manufacturing. Assembling the Jetson One requires test templates, which are also printed on a Sinterit SLS 3D printer.

“We have a welded aluminium space frame and we need to know where to mount all the different components on it. So we are able to 3D print jigs and drill guides, which is a quick process for us to go from CAD to the actual product. We made the part and printed it on the 3D printer, and we also made the jig. Building the nozzles is much easier because there are not as many measurements and the likelihood of errors is much lower,” says Alec Bialek.

Lisa X meets all needs for now. But is a compact SLS printer good enough in the long run? “You also want a bigger printer, just as you always want a bigger CNC machine. Here’s how it works. But for what we had and what we reasonably need, the Lisa X works very well and will work well for future Jetson products,” Bialek concludes.

Jetson One will soon take to the skies

The world is ready and demand is high. The intentions of Jetson’s founders are becoming a reality thanks to SLS 3D printing. They have done a tremendous amount of work to make flying as easy as possible. And the result matches it. When you hop into the Jetson One, there are only two levers at your disposal: the “elevator stick” and the “go stick”. That’s all you need to fly. That’s how simple it is. The revolution can begin. Also thanks to SLS 3D printing.