PBT optimal

The most cost-effective material sought after for its

high rigidity and excellent detail

Description

Polybutylene terephthalate (PBT) enables significant cost savings in the development and small-scale production of components, particularly in the field of electrical and electronic components. It is popular because of its high rigidity, excellent detail and exceptional resistance to damage. It has properties such as electronic insulation and solvent resistance. It provides a high level of detail quality and ensures the lowest possible cost per part.

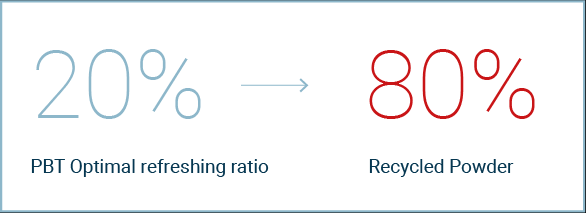

What is the refresh rate?

It is the ratio of the minimum amount of fresh powder needed in the material mix used in the SLS 3D printer. A lower refresh ratio means better material cost efficiency.How does it work?

The amount of fresh powder needed is automatically calculated by our software and displayed on the printer screen when the print job is complete. Simply add the displayed amount of material to the used material mixing cycle and you can start your next job with fresh material.Reuse of powder

Vlastnosti

- The most economical printing

- Exceptionally high rigidity

- High resistance to chemicals

- Excellent reproduction of intricate details

Aplikace

- Hot forming moulds

- Medical and dental applications

- Manufacture of electrical and electronic components

- Manufacture of rigid tooling components